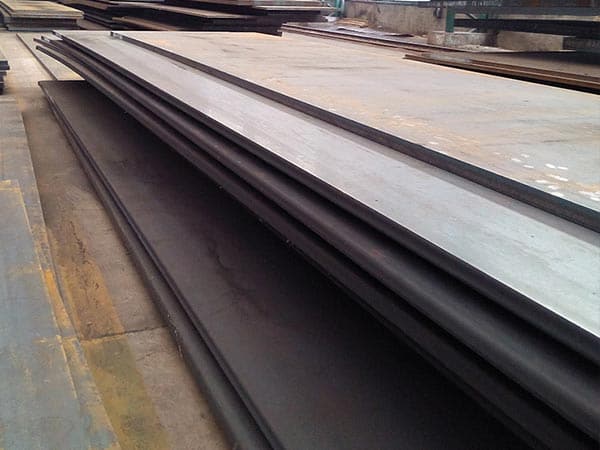

Hot Rolled 1.0984 steel for boom for oil tank

15Mo3 steel is a kind of pearlitic heat-resistant steel, which can still show its characteristics under high temperature and long time load. 15Mo3 steel is used for heating surface of 1.0984 steel for boom low and medium pressure boiler (working pressure

15Mo3 steel is a kind of pearlitic heat-resistant steel, which can still show its characteristics under high temperature and long time load. 15Mo3 steel is used for heating surface of 1.0984 steel for boom low and medium pressure boiler (working pressure is generally not more than 5.88MPA, and working temperature is below 450 ℃). 15Mo3 steel is widely used in petroleum, chemical industry, power station, boiler and other industries. 15Mo3 steel is used to make reactor, heat exchanger, separator, spherical tank, oil and gas tank, liquefied gas tank, etc.

Good impact resistance. Wear resistant composite steel plate uses low carbon steel or low alloy, stainless steel and other toughness as the base material. The 1.0984 steel for boom metal material not only has good wear resistance, but also can withstand the impact and wear of falling from high to low in the transportation process. It has good heat resistance. Vanadium, molybdenum and other 1.0984 steel for boom alloy materials are added into the alloy wear-resistant layer during the manufacturing process, so it can be used and worn at high temperature ≤ 800 ℃. Compared with ordinary 1.0984 steel for boom carbon steel substrate, it can only be used below 380 ℃, while low alloy heat-resistant steel plate can work below 540 ℃. This shows how high the heat resistance coefficient of wear-resistant steel plate is. Good corrosion resistance.

Quenching is a heat treatment process in which steel parts are heated to above the critical temperature, and after proper heat preservation, the parts are quickly cooled to room temperature in water or oil, so that martensite transformation occurs. The hardness of the quenched 1.0984 steel for boom increases sharply. Quenching is to prepare the organization for adjusting and improving the performance of 1.0984 steel for boom during tempering, while tempering determines the performance and life of the workpiece.

We have huge stocks for carbon steel plates, high strength low alloy steel materials, weather resistant steel sheets, wear resistant steel plates, boiler plates, pipeline steel, etc. Those stocks can be delivered within 10 days after deposit. We update 1.0984 steel for boom stock list regularly. But the stock changes quickly. It needs to check with warehouse specially when you have urgent needs. Welcome to contact us and book steel materials stocks.

Our company regularly visits customers, consults and follows up the after-sales service, and directly solves problems for customers. In the use of our steel materials, whether quality problems or not, the after-sales will help solve the problem as soon as possible. We promise free life-long replacement for any product quality problems. The sound after-sales service system make you free from worries.

Leave a message