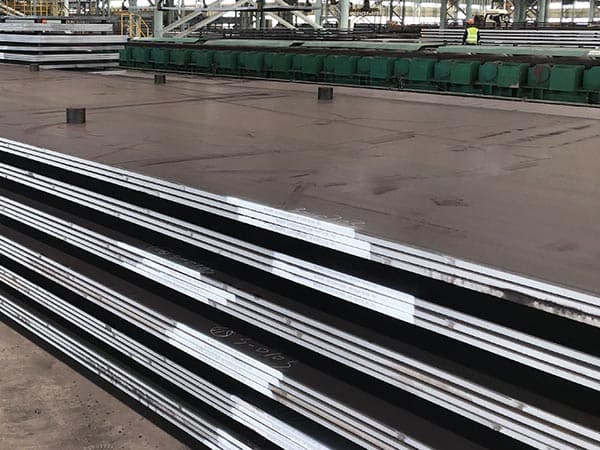

Galvanized sheet metal en 10149-2 s700mc automotive steel material from factory

Our marine steel CCS Grade A hot rolled plates, en 10149-2 s700mc automotive steel material specification available now has 6*3300*4000, 5*1500*4500, 12*2700*9600, 9*3200*10400, 11*1790*7990, 6*3380*4600, 5*1500*11700, 12*2700*9000, 12.5*3390*9260, 13*175

Our marine steel CCS Grade A hot rolled plates, EN 10149-2 S700MC automotive steel material specification available now has 6*3300*4000, 5*1500*4500, 12*2700*9600, 9*3200*10400, 11*1790*7990, 6*3380*4600, 5*1500*11700, 12*2700*9000, 12.5*3390*9260, 13*1750*8400, 7*3620*9700, 12*2500*8350, 14.5*1830*6300, 15*3000*4200, 20*2750*5000, 7*1760*4250, 12*3000*10500, 12*3660*6070, 13*2000*4700, 13*2810*4100, 17*1910*7860, 12*2700*11450, 12*3800*9740.

The company adheres to the management concept of "people-oriented, talent is concerned", develops business with the spirit of "believing strength, practical style, en 10149-2 s700mc automotive steel material professional service and dare to compete", and provides customers with "professional, value-added and effective" service support. For the company's development and take-off, we work together to move forward and create a better en 10149-2 s700mc automotive steel material tomorrow!

keyword} product plate production process:Raw materials (scrap steel, pig iron and molten iron) → electric furnace (100 tons electric arc furnace smelting) → converter → LF furnace molten steel refining treatment → VD or VOD furnace molten steel vacuum treatment → die casting (various key die casting lines) or continuous casting (large Slab caster) (50 tons of slab electroslag furnace for remelting a steel ingot) → heating (continuous furnace and soaking furnace) → steel plate rolling (4100 and 4200mm rolling mills) → steel plate heat treatment (normalizing and tempering) Quality) →Steel plate cutting inspection→Inspection

The effect of alloy elements on the properties of heat treatment methods for thick steel plate: the performance of heat treatment method reflects the difficulty coefficient level of heat treatment process and the tendency of defects caused by heat treatment process. The key points include cutting performance, over temperature sensitivity, quenching aging tendency and air oxidation carburizing tendency. en 10149-2 s700mc automotive steel material, Carbon steel has high machinability, and slow cooling method can be used in heat treatment, which can reduce the deformation and cracking tendency of the products. The addition of Mn and Si will increase the over temperature sensitivity of steel.

After the order is finished, our after-sales service center will send an email to make a feedback about our steel products' quality. We have phone service every three months to remind our customers of the possible problems and collect advices or suggestions in quality and service. Upon the collection of advices or suggestions, our after-sales service will quickly make technical solutions to wipe out the customer problem.

Leave a message