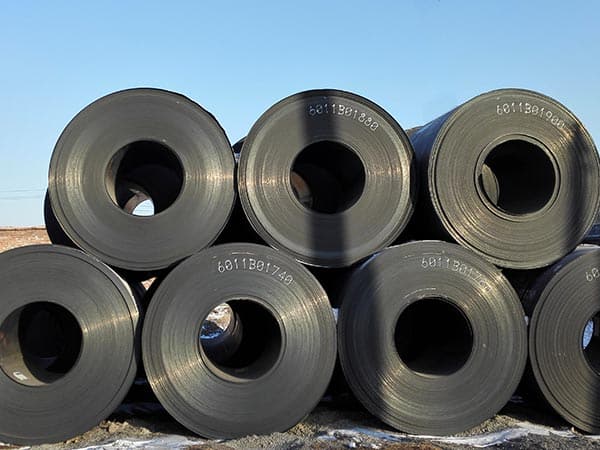

EN10149-2 S700MC hot rolled pickled t700 steel price remains high and fluctuate

Beijing machining center has more than 1000 employees, including 360 technicians, 28 engineers, 6 senior welders, 15 professional welders, 52 bachelor's degree, 3 doctor's degree, and 8 R & D team. It is a professional EN10149-2 S700MC hot r

Beijing machining center has more than 1000 employees, including 360 technicians, 28 engineers, 6 senior welders, 15 professional welders, 52 bachelor's degree, 3 doctor's degree, and 8 R & D team. It is a professional EN10149-2 S700MC hot rolled pickled t700 steel production team combining theory and practice. With an annual output of 80000 tons, looking forward to the future, our company continues to strengthen the advantages of EN10149-2 S700MC hot rolled pickled t700 steel leading suppliers in the four steel fields of steel plate, steel pipe, stainless steel and special steel.

The difference between Q235 steel and Q345 steel:The lower limit of yield strength of Q235 steel is 235MPa, the lower limit of yield strength of Q345 steel is 345MPa. The EN10149-2 S700MC hot rolled pickled t700 steel alloy content of Q235 steel is common carbon steel and Q345 steel is low alloy steel. Q345 steel is used for structures, mechanical parts, building structures, general metal structures bearing dynamic loads such as medium and low pressure vessels, oil tanks, vehicles, cranes, EN10149-2 S700MC hot rolled pickled t700 steel mining machinery, power stations, bridges, etc..

EN10149-2 S700MC hot rolled pickled t700 steel, low alloy high strength steel can meet the requirements of various structures (such as large bridges, pressure vessels, ships, etc.) in engineering. At the same time, it is required to reduce the weight of the structure, improve the reliability and save materials and resources. Low alloy high strength steel is mainly used to manufacture various engineering structures with high strength requirements, such as bridges, ships, vehicles, high pressure vessels, oil and gas pipelines, large steel structures, etc. Because low alloy high strength steel can obtain high strength without complicated treatment process or even heat treatment, the quality of engineering structure is greatly reduced. Therefore, low alloy high strength steel is commonly used to replace the general carbon structural steel.

The steel plate cutting and processing instructions are as follows: steel plate cutting and steel plate cutting processing, as well as EN10149-2 S700MC hot rolled pickled t700 steel steel plate zero cutting processing. There are semi-automatic flame cutting, fully automatic CNC cutting, laser cutting and water cutting. The thickness range of steel plate that can be cut is 20650mm. In terms of EN10149-2 S700MC hot rolled pickled t700 steel steel plate cutting types, there are Q235B common plate, Q345B low alloy plate and 45 carbon bonded plate.

EN10149-2 S700MC hot rolled pickled t700 steel, St52-3 steel is a low alloy, high strength structural steel which can be readily welded to other weldable steel. St52-3 steel’s mechanical properties is yield strength more than 355 MPa, tensile strength 490-630Mpa. For St52-3 steel, the C element content is 0.24%, the Si element content is 0.55% max, the Mn element content is 1.60% max, the P element content is 0.045% max, the S element content is 0.045% max.

As one of the large professional metallurgical manufacturers in China, the strength of the brand, quality assurance, professional after-sales. Every day we are making unremitting efforts to challenge higher quality EN10149-2 S700MC hot rolled pickled t700 steel products and more satisfactory services. Customer demand is our pursuit, and win customer satisfaction with quality. BBN after-sales team is responsible to solve the problem of technical support and quality, service complaints.

Leave a message