Why is water seeping out of the slit when cutting S700MC hot rolled steel for car gear

The cold rolling precision bright pipe system produced by our factory has smooth appearance, uniform wall thickness, no oxide layer and high precision. The inner hole of S700MC hot rolled steel for car gear steel pipe can be divided into round, spline and

The cold rolling precision bright pipe system produced by our factory has smooth appearance, uniform wall thickness, no oxide layer and high precision. The inner hole of S700MC hot rolled steel for car gear steel pipe can be divided into round, spline and plum blossom, which is widely used in automobile, motorcycle, electric power, petrochemical, ship, aerospace, bearing, pneumatic components, oil cylinder, boiler equipment, medical equipment, fitness equipment and other industries. Materials can be divided into: 10#, 20#, 35#, 45#, 40Cr, 16Mn, etc. According to the needs of users, we can make all kinds of national standard non-standard precision pipes. Special S700MC hot rolled steel for car gear materials and specifications can be ordered in advance.

The S700MC hot rolled steel for car gear atmospheric corrosion resistance of high weather resistant structural steel is better than that of welding structural weathering steel, and is mainly used for bolt connection, riveting and welding structural parts for vehicles, containers, buildings, towers and other structures. But the welding performance of welding structural weathering steel is better than that of high weather resistant structural steel, and the welding structural weathering steel is mainly used for welding structural parts for bridges, buildings and other structures.

Looking to the future, our company will make its main business more competitive while carrying out diversified, extensive, green and harmonious development modes, so as to be the most competitive stainless steel S700MC hot rolled steel for car gear producer in the world as well as a worldwide first-class enterprise. With ten years cooperation with these big mills, now we are the agent of super stainless steel mills in China.

After extrusion, the S700MC hot rolled steel for car gear tube shall be removed for sizing. The sizing machine uses a cone-shaped bit to rotate into the steel embryo at high speed to drill holes to form steel pipes. The inner diameter of the steel pipe is determined by the outer diameter length of the drill bit of the sizing machine. After sizing, the steel pipe will enter the cooling tower and be cooled by water spray. After cooling, the steel pipe will be straightened. After straightening, the steel pipe is sent to the metal flaw detector (or hydraulic test) by the conveyor belt for internal flaw detection.

S700MC hot rolled steel for car gear, q345r pressure vessel steel is an ordinary low alloy steel, which is commonly used for boiler and pressure vessels. The delivery status of Q345R pressure vessel steel is hot rolling or normalizing. The properties of Q345R pressure vessel steel are similar to those of Q345 steel (16Mn). The yield strength of 16mm steel plate is greater than 345 Mpa, the tensile strength is 510-640 Mpa, the elongation is more than 21%, and the zero degree V-shaped impact energy is greater than 34J. The process reference standard of Q345R pressure vessel steel is GB713.

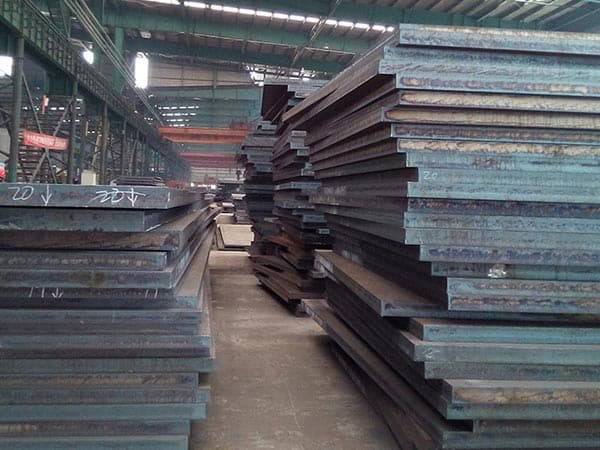

The company specializes in hot rolled plates producing, steel plate processing, steel plates cutting, carbon steel plate weldding and exporting of wide and thick steel plates. BBN company has high-quality CNC S700MC hot rolled steel for car gear steel plate cutting processing equipment, professional technical personnel, and supporting marketing and after-sales service system. Sincerely welcome new and old customers to visit our company, BBBN company will always be your reliable choice.

The company's after-sales service tenet is "customer first, timely guarantee, enthusiastic service and effective work". In order to establish a set of perfect after-sales service system and strict management system, so that the after-sales service can be effectively guaranteed. The company has set up after-sales service department to ensure timely, unique and effective response to every user's request, coordinate internal resources internally, and put an end to all evasion and delay.

Leave a message