What is the ZQS700L automobile structure steel plate hot rolling

The company's ZQS700L automobile structure steel plate steel products are sold all over the world with high quality and low price. We can process and cut all kinds of special-shaped parts according to your requirements, or we can set and roll futures

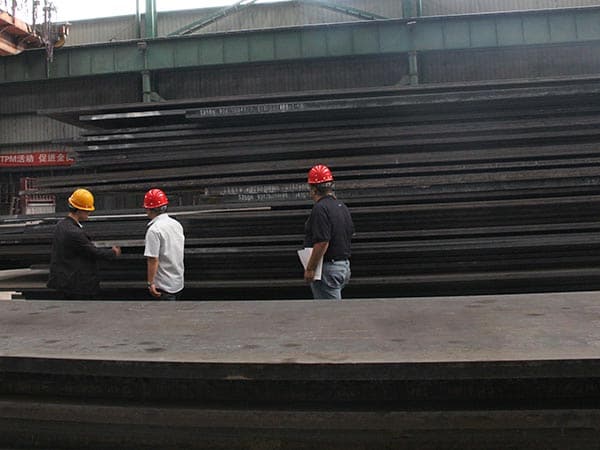

The company's ZQS700L automobile structure steel plate steel products are sold all over the world with high quality and low price. We can process and cut all kinds of special-shaped parts according to your requirements, or we can set and roll futures of all kinds of material specifications according to your requirements, with fast delivery time. We sincerely welcome new and old customers from all walks of life to contact us for ZQS700L automobile structure steel plate business negotiation. With the enthusiasm, good reputation and professionalism of our staff, we will provide excellent services to our valued customers in all aspects, so as to achieve common development and prosperity.

The mechanical properties of ZQS700L automobile structure steel plate steel plate are related to elastic or inelastic reaction or related to stress-strain relationship. Tensile strength, yield point, elongation and impact absorption energy are the main indexes to express the mechanical properties of hot rolled steel plate. Its value represents the ability of steel ZQS700L automobile structure steel plate to resist various actions, which is the main criterion to evaluate the quality of steel material, and also the main basis for material selection and strength calculation in steel plate design.

Different form ZQS700L automobile structure steel plate, boiler steel plate is one of the most critical materials in boiler manufacturing. Boiler steel plate mainly refers to the hot-rolled special carbon steel and low alloy heat-resistant steel plate used to manufacture important components such as the shell, drum, header end cover, support and hanger in the boiler. Boiler steel plates are often working under medium, high temperature and high pressure. In addition to withstand higher temperatures and pressures, boiler steel plates are also subject to impact, fatigue loads, and water and gas corrosion, resulting in poor working conditions.

The work performance of ZQS700L automobile structure steel plate etc. steel material is mainly depended on its chemical composition, mechanical properties etc. parameters. The higher strength the steel has, the less quantity steel is needed to achieve same strong effect of the steel structure. However, the steel strength varies with the thickness. So please take steel thickness into consideration when evaluating the steel strength. For a certain steel, its strength also has something to do with the steel shape. For example, for a same steel grade, the steel strength is different for steel plates and pipes.

Hot Rolled Plates Products TestingBBN STEEL can supply many tests and analysis done to examine them before and after the manufacturing. As the ZQS700L automobile structure steel plate raw material is fetched by us the steel undergoes vacuum treatment, product analysis, additional tensile test, simulated post weld heat treatment, and impact test. After the steel is converted to steel plates they undergo the drop-weight test, hot tensile test, ultrasonic test, the practical examination through examination, and the vacuum carbon deoxidized steel."

The company is mainly engaged in ZQS700L automobile structure steel plate steel plates manufacturing and deep processing, sales and distribution. It is committed to building a complete modern steel purchase and sale network. Here we would like to express our sincere gratitude to our old and new friends who have always given care, support, affirmation and help, and sincerely hope to establish a long-term cooperative relationship with them for mutual benefit, win-win and common development, and work ZQS700L automobile structure steel plate together for a better tomorrow.

The after-sales service department will pay return visit to each customer by call or email, report problems found during the return visit in time, and discuss with the production and quality inspection center to propose effective solutions and follow up in a timely manner, so as to ensure the benefits each customer are fully guaranteed, and to provide customers with more value-added services.

Leave a message