What is the s420mc galvanealed coil density surface treatment

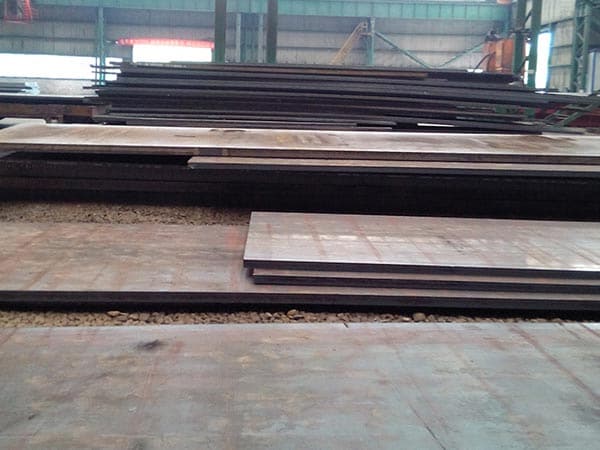

As a leading hot rolled plate mill in China, We manufacture and export carbon steel and alloy s420mc galvanealed coil density steel plates in different sizes and of different thickness. We have an adept and proficient team of professionals in addition to

As a leading hot rolled plate mill in China, We manufacture and export carbon steel and alloy S420MC galvanealed coil density steel plates in different sizes and of different thickness. We have an adept and proficient team of professionals in addition to our responsive staff that is ever alert for any customer queries and requisites. If you are experiencing difficulty in selecting the correct s420mc galvanealed coil density steel plates for your business, we have a team of experts who can give you the best advice on steel plates, a significant contributor that can flourish your business.

GB711-2011 Chinese steel standard is used in the manufacture of steel plates with a s420mc galvanealed coil density thickness of not more than 150mm for navigating ships, fishing boats and marine engineering structures in ocean, coastal and inland waterway areas. CCS/NV/GL550 steel is a structural steel for ships and marine engineering, divided into four quality grades A, D, E, F, namely AH550, DH550, EH550, FH550, H is high-strength building materials, and 550 is the lower yield strength.

It has good toughness. By strictly controlling the chemical composition, reducing the content of s420mc galvanealed coil density harmful elements and selecting reasonable heat treatment conditions, NM360 steel plate has good toughness. Therefore, the highly reliable structural parts can be constructed according to the brittle failure of wear-resistant components. Uniform and beautiful quality, s420mc galvanealed coil density using advanced technology and equipment, combined with high and scientific technical management, the material and shape of the product are even and consistent.

With the increase of carbon content in the steel material, the yield point and tensile strength increase, but the plasticity and impact decrease. When the carbon content is more than 0.23%, the welding performance of the steel material becomes worse. Therefore, the carbon content of low alloy structural steel used for welding is generally less than 0.20%. The high carbon content can also reduce the atmospheric corrosion resistance of steel material, and the high carbon steel in the open air is easy to rust; in addition, carbon can increase the cold brittleness and aging sensitivity of s420mc galvanealed coil density etc. steel material.

A204 Grade A steel chemical composition(%)Carbon: 0.18-0.25 Manganese max.: 0.90Phosphorus Max.: 0.025Sulfur Max.: 0.025Silicon: 0.15-0.40Molybdenum: 0.45–0.60s420mc galvanealed coil density, A204 Grade A steel mechanical propertiesTensile strength, kis [MPa]: 265-85 [450-585]Yield strength, min, kis [MPa]: 37 [255]Elongation in 8 in. [200 mm], min, %: 19Elongation in 2 in. [50 mm], min, %: 23

The company has a high-quality management, technology and R&D team, and adopts independent research and development, domestic innovative process optimization combination. Relying on advanced manufacturing technology and sophisticated production testing equipment, it has ensured the high quality of products s420mc galvanealed coil density and won a good reputation. We can offer various kinds of steel materials in GB, ASME, ASTM, JIS, DIN, EN, API standards and specifications.

When providing technical services on site, the after-sales personnel shall strictly abide by the safety rules and regulations of the construction site, consciously take safety protection measures (such as wearing safety helmet when entering the construction site), accept the supervision and management of the site; without permission on the construction site, they shall not dismantle, smear or damage any goods; the commissioning of contract goods shall be carried out under the supervision of the site supervisor If necessary, it shall be approved by the site supervisor or the person in charge of the project department.

Leave a message