What is the production process of s550mc high strength steel auto plate as per en 10149

The company adheres to green development, supported by scientific and technological innovation and technological progress, vigorously advocates the s550mc high strength steel auto plate as per en 10149 production and life style of saving, environmental pr

The company adheres to green development, supported by scientific and technological innovation and technological progress, vigorously advocates the S550MC high strength steel auto plate as per en 10149 production and life style of saving, environmental protection, civilization and low carbon, adheres to the new industrialization road and the sustainable development road. Actively carry out international trade and maintain stable economic and trade relations with more than 80 countries and regions including the United States, Germany, France, the United Kingdom, Japan, South Korea and Australia.

SM490B plate is a kind of structural steel produced according to Japanese Standard JIS G3106. Min. tensile strength of SM490B plate is 490MPa. SM490B plate is mainly used in buildings, bridges, ships, rail vehicles, oil tanks, containers and other buildings requiring high-level weldability. The delivery state is hot rolling for SM490B plate, s550mc high strength steel auto plate as per en 10149 with thickness less than 80mm; and the delivery state is normalizing for SM490B steel plate with thickness more than 80mm.

The s550mc high strength steel auto plate as per en 10149 processing performance is good. Due to the uniform control of steel plate performance, excellent performance coordination and good toughness guarantee, the steel plate bending processing, drilling, cutting and other mechanical processing properties are excellent. In addition, the surface of the s550mc high strength steel auto plate as per en 10149 steel plate is smooth and beautiful by inhibiting and removing oxide scale from slab heating to rolling process and heat treatment in furnace without oxidation atmosphere.

Hydrogen (H) is the most harmful element in general steel such as s550mc high strength steel auto plate as per en 10149. Hydrogen dissolved in steel will cause hydrogen embrittlement, white spots and other defects. Hydrogen, like oxygen and nitrogen, has very little solubility in solid steel. It dissolves into liquid steel at high temperature, and accumulates in the structure without time to escape when cooling, forming high-pressure micro pores, which greatly reduce the plasticity, toughness and fatigue strength of steel, and even cause cracks and brittle fracture in severe cases. "Hydrogen embrittlement" mainly occurs in martensitic steel, but not very prominent in ferrite steel, and generally increases with hardness and carbon content.

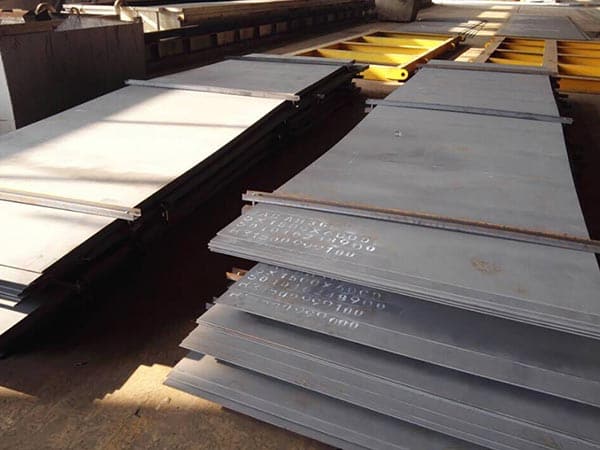

5mm 6mm hot rolled thin plates product s550mc high strength steel auto plate as per en 10149 inventory: 5*3000*8000, 5*3000*8400, 6*2800*9390, 5*2800*11880, 6*2614*7050, 5*3000*11650, 5*3000*9900, 5*3000*8300, 6*2854*8200, 5*2790*10500, 6*2854*9680, 5*3000*8800, 6*2854*7480, 6*2614*9250, 5*2990*10470, 5*3000*8600, 6*2800*9390, 6*2854*8500, 5*2990*10400, 5*2990*9000, 6*2854*6480, 6*2854*6800, 5*3000*7550, 6*2854*9390.

If you want to get the ASTM A573 Grade 70/A573 Gr.70 carbon manganese silicon steel plates steel price, please do not hesitate to contact us. Any need in s550mc high strength steel auto plate as per en 10149 ASTM A573 Grade 70/A573 Gr.70 carbon manganese silicon steel plates Chemical Composition and Mechanical Properties, please feel free to contact us by email or calling to us

The company attaches great importance to the cultivation of team spirit. Personal strength is weak. After sales service departments, leaders and subordinates often communicate with each other. Everyone often holds meetings to discuss their problems in after-sales service, discuss technical difficulties, discuss how to improve work efficiency, how to better deal with user complaints, etc.

Leave a message