What is the process principle of S900MC mechanical properties

Vigorously develop circular economy: the company adheres to the development path of circular economy, realizes the efficient utilization of energy and S900MC mechanical properties resources, implements "four closed circuits" for renewable gas, i

Vigorously develop circular economy: the company adheres to the development path of circular economy, realizes the efficient utilization of energy and S900MC mechanical properties resources, implements "four closed circuits" for renewable gas, industrial water, solid waste and waste heat steam according to the reduction of resource consumption - reuse - recycling, vigorously promotes advanced technologies such as energy-saving new technologies, new processes, S900MC mechanical properties new materials, and promotes the competition of enterprises Struggle.

H13 tool steel is the most widely used and most representative hot work die steel. Its main characteristics are:(1) S900MC mechanical properties has high hardenability and high toughness;(2) Excellent thermal crack resistance, water cooling can be used in the work place;(3) With moderate wear resistance, carburizing or nitriding processes can also be used to increase the surface hardness, but the thermal crack resistance should be slightly reduced.

The corten plates S900MC mechanical properties offer high tensile, yield and mechanical strength at the elevated temperature. These plates provide high toughness and harness at the high temperature and cryogenic temperature as well. The application of corrosion Resistant Steel Plates is- these plates are used in the number of industries like landscape building, an automobile company, fertilizers, marine industry. The plate is used in because of its good elasticity, ductility, thermal and electrical conductivity. We follow all the industry-standard both national and international standards.

When phosphorus, copper, chromium, nickel and other trace elements are added to the steel, S900MC mechanical properties, a dense and strong adhesive protective film will be formed on the steel surface, which will prevent the corrosion from spreading and developing inward, and protect the substrate under the rust layer, so as to slow down the corrosion rate. The amorphous spinel oxide layer of about 50 μ m ~ 100 μ m thickness formed between the rust layer and the substrate is compact and has good adhesion with the substrate metal.

If your record is for special steel angle size, email us your customized size when your order is equal or bigger than our minimum quantity. A588 steel angle S900MC mechanical properties description: Steel grade: A588. Specification: ASTM A588. Technology S900MC mechanical properties: hot rolled. Type: equal & unequal. Length: 6 m, 9 m, 12 m or per your request. Equal angle: Size: 20 × 20 mm - 200 × 200 mm. Thickness: 3 to 22 mm. Length: 6 m, 9 m, 12 m or per your request. Unequal angle: Size: 20 × 30 to 90 mm × 250 mm. Thickness: 3 to 15 mm. Length: 6 m, 9 m, 12 m or per your request. Note: Special angle S900MC mechanical properties steel sizes are available if your order quantity surpasses the minimum.

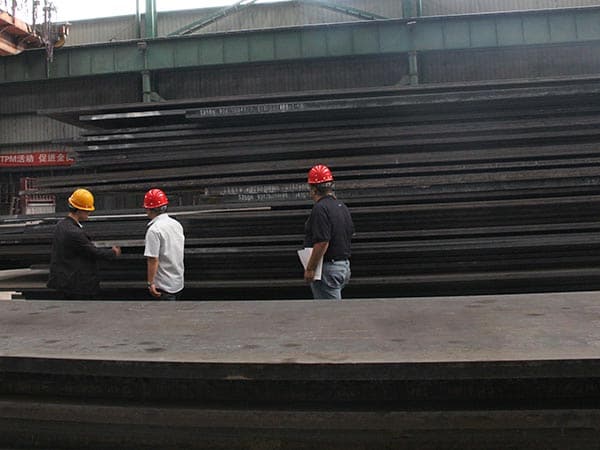

We have huge stocks for carbon steel plates, high strength low alloy steel materials, weather resistant steel sheets, wear resistant steel plates, boiler plates, pipeline steel, etc. Those stocks can be delivered within 10 days after deposit. We update S900MC mechanical properties stock list regularly. But the stock changes quickly. It needs to check with warehouse specially when you have urgent needs. Welcome to contact us and book steel materials stocks.

The company is deeply supported and loved by customers with its unique business philosophy and business model. The company has always been adhering to the "credibility first, integrity-based, quality first" purpose, and sincerely serve new and old customers. Over the past twenty years, the company has won the trust of customers by relying on good service and good reputation. Our aftersales team’s main responsibility is to deal with quality feedback and complaints from Customer.

Leave a message