What is the difference between fe 420 steel equivalent & Q235B?

In recent years, in line with the development trend of iron and fe 420 steel equivalent steel industry at home and abroad, we have accelerated the transformation of development mode, promoted structural adjustment, and formed a rich product series of medi

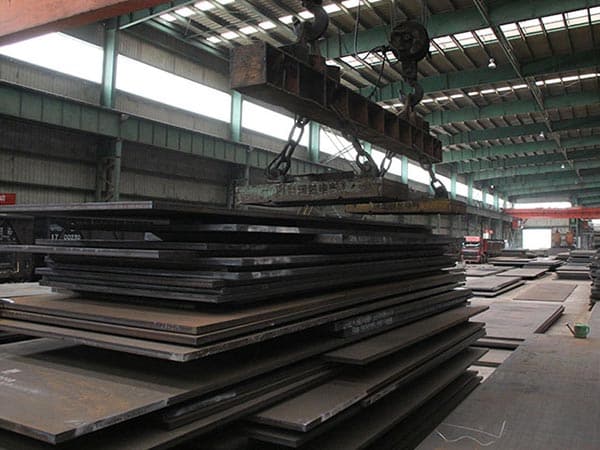

In recent years, in line with the development trend of iron and fe 420 steel equivalent steel industry at home and abroad, we have accelerated the transformation of development mode, promoted structural adjustment, and formed a rich product series of medium and thick plates, hot rolled steel coils, profiles, steel pipes, etc., which fe 420 steel equivalent are widely used in automobiles, long-span bridges, railways, machinery, ocean and so on fields. Meanwhile, we also provide deep processing for the steel materials.

SA387 Gr.12 Cl.2 steel data is suitable for the essence and gas treatment in hydrogenation reaction and conversion equipment at high temperature. It is a chrome molybdenum carbon alloy steel for use in weldable pressure vessels and industrial boilers. The maximum thickness of the steel plate can reach 250mm. According to different fe 420 steel equivalent thickness and impact requirements, the delivery situation of SA387 Gr.12cl.2 steel plate is: normalizing and tempering or normalizing and rapid cooling and tempering.

The excellent properties of wear resistant steel plate meet the strict requirements of high strength, high wear resistance, stability, straightness and surface quality. The combination of high hardness, high strength and excellent impact toughness makes fe 420 steel equivalent plate become an ideal material for a wide range of applications. The production thickness of wear resistant steel plate is generally between 8-100mm.

The effect of nitrogen (N) on the properties of fe 420 steel equivalent and so on steel is similar to that of carbon and phosphorus. With the increase of nitrogen content, the strength of steel can be significantly improved, especially the plasticity, especially toughness, and the weldability will be decreased, and the cold brittleness will be intensified. At the same time, aging tendency, cold brittleness and hot brittleness will be increased, which will damage the weldability and cold bending property of steel. Therefore, the nitrogen content in fe 420 steel equivalent and so on steel should be reduced and limited as much as possible. Generally, nitrogen content should not be higher than 0.018%.

Hot Rolled Plates fe 420 steel equivalent MachiningAfter final forging/forming and Heat treatment process, all the pipe Fittings, Flanges, Fasteners, Etc. are sent for machining i.e. and preparation, O/D and I/D matching as per dimensional codes. An Expert Q.C. engineer is involved and he keeps constant vigil on every machining operation. Step machining is carried out as required by the codes. GO and NO-GO gauges are used to check the O/D & I/D of the fittings, Flanges, etc.

We are leading supplier of pipeline steel. The pipeline steel in usually in forms of pipeline steel coils, pipeline steel sheet, pipeline steel plate and pipeline steel pipes. And the most popular standard is API 5L. For questions about fe 420 steel equivalent pipeline steel, such as X70 steel properties, API 5L X42 steel properties, difference between API 5L PSL1 and API 5L PSL2, API 5L grade B steel price, please feel free to communicate with us.

The 365 day service system is implemented, and the business, loading and delivery are handled as usual in holidays and festivals. Actively help users solve difficulties. When users encounter difficulties in handling business, they should actively coordinate with the external solution; if they need to solve the problems internally, they should solve them in a timely manner without prevarication and wrangling. In line with the fe 420 steel equivalent principle of "fairness, justice and timeliness", coordinate with relevant departments and deal with all kinds of objections in a timely manner.

Leave a message