What is the difference between B750L plate zero cut sheet & plate steel?

The company adheres to the business philosophy of "excellent quality and integrity", aims to create a first-class enterprise in the B750L plate zero cut industry, takes circular economy and resource reuse as the main line, takes energy conservat

The company adheres to the business philosophy of "excellent quality and integrity", aims to create a first-class enterprise in the B750L plate zero cut industry, takes circular economy and resource reuse as the main line, takes energy conservation, emission reduction and sustainable development as the purpose, relies on advanced equipment, perfect transportation infrastructure and good reputation, and strives to become a leading enterprise in the B750L plate zero cut industry with scientific management, high quality, first-class service and harmonious development

Our main specifications of medium and heavy plates are thickness 6.0-180mm and width 1400-2700mm. In addition, the ship steel plate has been approved by the factories of the eight-nation classification society such as CCS, ABS, BV, LR, GL, NK, KR, and DNV. Our B750L plate zero cut, medium and heavy plates are widely used in manufacturing, logistics, and automotive industries such as construction machinery, mold processing, ships, bridges, high-rise buildings, pipeline transportation, automobile girders, automobile bridge shells, and pressure vessels.

The excellent properties of wear resistant steel plate meet the strict requirements of high strength, high wear resistance, stability, straightness and surface quality. The combination of high hardness, high strength and excellent impact toughness makes B750L plate zero cut plate become an ideal material for a wide range of applications. The production thickness of wear resistant steel plate is generally between 8-100mm.

The B750L plate zero cut, wear resistant steel plate is composed of low carbon steel plate and alloy wear-resistant layer, and the alloy wear-resistant layer is 1/3 ~ 1/2 of the total thickness. The alloy wear-resistant layer and the base plate are metallurgically bonded. When working, the base plate provides comprehensive properties such as strength, toughness and plasticity to resist external forces, and the alloy wear-resistant layer provides wear-resistant properties to meet the requirements of specified working conditions.

Chemical composition of Q420 steel: C ≤ 0.20, Si ≤ 0.50, Mn ≤ 1.70, P ≤ 0.035, S ≤ 0.035, Nb ≤ 0.07, V ≤ 0.20, Ti ≤ 0.20, Cr ≤ 0.30, Ni ≤ 0.80, Cu ≤ 0.30, N ≤ 0.015, Mo ≤ 0.20. The mechanical properties of Q420 steel are: yield strength ≥ 340 MPa, tensile strength 500-680 MPa, elongation after fracture ≥ 18%, impact energy 34J. B750L plate zero cut, Q420 steel has good mechanical properties and weldability, good cold and hot workability. Q420 steel is mainly used for manufacturing mining machinery, heavy vehicles, ships, bridges, medium and high pressure boilers, vessels and other large welding and structural parts.

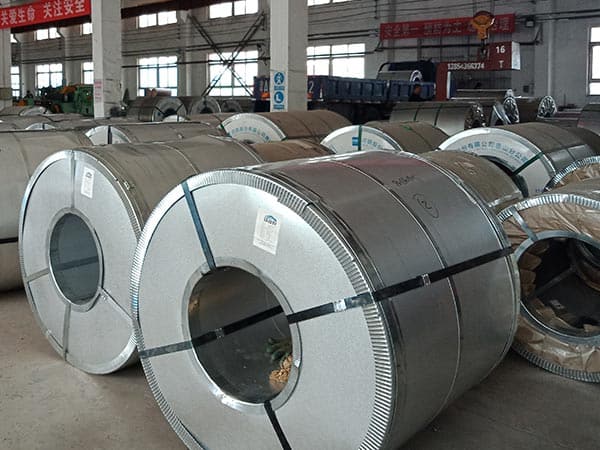

We have huge stocks for carbon steel plates, high strength low alloy steel materials, weather resistant steel sheets, wear resistant steel plates, boiler plates, pipeline steel, etc. Those stocks can be delivered within 10 days after deposit. We update B750L plate zero cut stock list regularly. But the stock changes quickly. It needs to check with warehouse specially when you have urgent needs. Welcome to contact us and book steel materials stocks.

The company's after-sales service tenet is "customer first, timely guarantee, enthusiastic service and effective work". In order to establish a set of perfect after-sales service system and strict management system, so that the after-sales service can be effectively guaranteed. The company has set up after-sales service department to ensure timely, unique and effective response to every user's request, coordinate internal resources internally, and put an end to all evasion and delay.

Leave a message