What is the BS700MC cold forming steel shapes

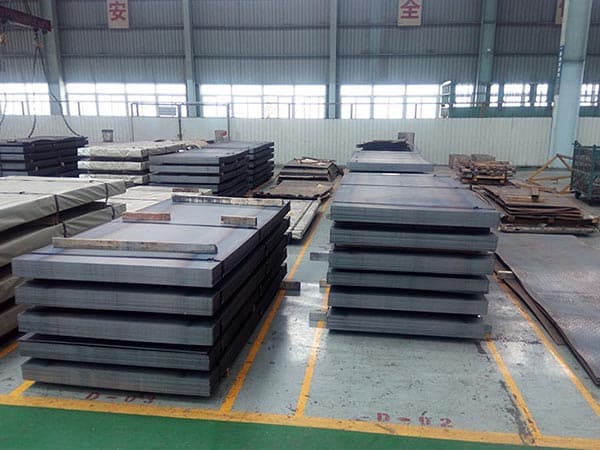

At the same time, the company operates a variety of products of related iron and BS700MC cold forming steel steel enterprises. Annual sales of steel 3.6 million tons, standing stock of 400000 tons, has developed more than 10000 users. The company has a fi

At the same time, the company operates a variety of products of related iron and BS700MC cold forming steel steel enterprises. Annual sales of steel 3.6 million tons, standing stock of 400000 tons, has developed more than 10000 users. The company has a first-class marketing service system, strong storage and transportation capacity and supporting supply, cutting distribution capacity, and gradually build it into an important marketing channel. The company has obtained BS700MC cold forming steel ISO9001:2000 quality system certification, A-level credit unit of the people's Bank of China, and is an excellent supplier of many large state-owned enterprises.

45Mn carbon structural steel can obtain better comprehensive mechanical properties after quenching and tempering. The cutting performance is still good, but the welding performance is poor, the cold deformation plasticity is low, and there is a tendency to temper brittleness. It is generally used in the quenched and tempered state, and BS700MC cold forming steel can also be used in Used in quenched and tempered or normalized state.

The surface of alloy steel coil is specially treated during processing. The wear resistance of steel coil and plate made of alloy steel is much better than that of traditional rolling plate, and the cost is also low. The heat resistance and high temperature resistance of alloy steel coil is better than that of traditional rolling plate, and it will not deform easily. Besides, the strength of the BS700MC cold forming steel, alloy steel is very high, it is not easy to break and can be used for a long time.

The common delivery status of BS700MC cold forming steel, SA516 Gr 70 plate is as follows: 1) SA516 Gr 70 plate quenching: the process of rapid cooling after heating to the temperature above the phase transformation point. 2) SA516 Gr 70 plate normalizing: after heating above the phase transition temperature, it is cooled normally (in air). 3) SA516 Gr 70 plate annealing: heating to above the phase transition temperature, cooling slowly. 4) SA516 Gr 70 plate tempering: after quenching, it is heated to a certain temperature (lower than the quenching temperature), kept warm, and then cooled.

BS700MC cold forming steel, 13CrMo44 steel plate is a kind of steel which with Cr, Mo,Cr-Mo and mainly used for pressure vessels. The steel grade 13CrMo44 is according to DIN 17155 standard which with the yield strength of 242MPa. The DIN 17155 13CrMo44 steel plate chemical composition is the content of C is 0.15, Mn is 2.00, S is 0.03, Cu is 0.30, Si is 1.00, P is 0.045, Cr is 17 or 19 and the Ni is 8 or 10.

Analyze the advantages and disadvantages of the products against the competitive BS700MC cold forming steel products. Understand the industry situation and future trend. Understand the product brand positioning appeal point, focus on the crowd and development direction. Understand the layout of each market area, and form a big strategic layout view. Understand the basic operation and assessment standards of work responsibilities. Understand the situation of the cooperative customers.

The company has passed the ISO9001: 2008 quality system certification, strictly implemented the ISO9001 quality management system. Besides, we have continuously improved the after-sales service network to make every effort to provide more convenient, accurate and faster services for all customers. We will supervise the production, control the quality in the factory, Inspect the cargo before shipment, Issue the test report to sales department. From the steel prodcution to steel delivery, we always focus the whole process.

Leave a message