What are the welding precautions for S355MC cold rolled plate zero cut

At the same time of doing well in S355MC cold rolled plate zero cut production and operation, Yunnan company focused on completing the four phases of technical transformation construction projects, realizing industrial upgrading, improving equipment level

At the same time of doing well in S355MC cold rolled plate zero cut production and operation, Yunnan company focused on completing the four phases of technical transformation construction projects, realizing industrial upgrading, improving equipment level, and laying a good foundation for the future development of the company. In the S355MC cold rolled plate zero cut technological transformation project, pollution control facilities have been built synchronously, and a large number of comprehensive utilization projects, such as comprehensive sewage treatment and recycling project, blast furnace gas waste heat and residual pressure power generation, have been invested and constructed.

The quality of carbon steel is distinguished by the amount of sulfur (s) and phosphorus (P) in the steel. When the S355MC cold rolled plate zero cut sulfur content in carbon steel is not more than 0.050% and the phosphorus content is not more than 0.045%, it is ordinary carbon steel; when the sulfur content and phosphorus content in carbon steel are less than 0.040%, it is high-quality carbon steel; when the S355MC cold rolled plate zero cut sulfur content in carbon steel is less than 0.030% and the phosphorus content is less than 0.035%, it is high-quality carbon steel.

High-temperature boiler steel plates such as 15CrMoR plate, 12Cr1MoVR steel plate, ASME SA387 grade 22 steel, A387 Gr 91 boiler steel, ASME SA1017 Gr 23, SA1017 Gr 911, SA1017 Gr 122 steel, S355MC cold rolled plate zero cut, must have features of:Sufficient high temperature durability and durable plasticity;Good high temperature tissue stability;Good high temperature oxidation resistance (heat resistance);Good hot and cold processing technology (mainly refers to cold bending deformation and weldability), etc.

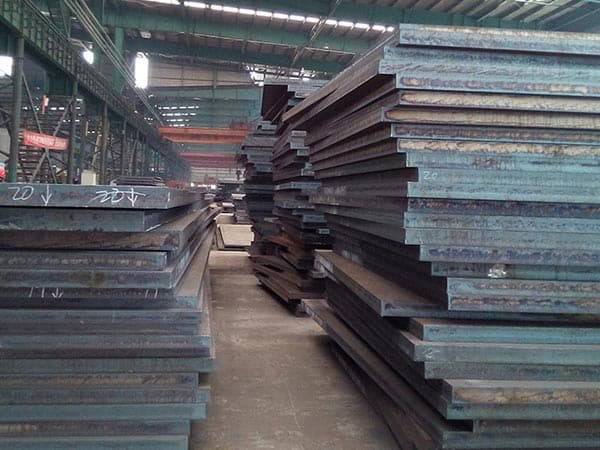

The steel such as S355MC cold rolled plate zero cut delivered in the hot-rolled state has a certain degree of corrosion resistance due to the high temperature, so it can be stored in the open air. However, this layer of oxide scale also makes the hot-rolled steel surface rough and the size fluctuates greatly. Therefore, the steel with smooth surface, accurate size and good mechanical properties is required to be produced by using hot-rolled semi-finished products or finished products as raw materials and then cold rolling.

20# seamless steel pipe chemical composition: C: 0.07-0.23, Si: 0.17-0.37, Mn: 0.35-0.65, Cr: 0.25, Ni: 0.30, Cu: 0.25. 20# seamless steel pipe mechanical properties: recommended heat treatment temperature: 910℃, tensile strength: 410 MPa, yield strength: 245 MPa, elongation: 25%, impact energy is not required. 20# seamless steel pipe hardness is higher than 10# seamless steel pipe. S355MC cold rolled plate zero cut, 20# seamless steel pipe has good weldability, no temper brittleness, and its machinability can be improved by water quenching. 20# seamless steel pipe can be used to make welded components, as well as parts with small load after forging, hot stamping and cutting.

Our steel products are widely used in petroleum and natural gas, chemical industry, shipbuilding, automobile manufacturing, power generation, mining, and other industries. The products S355MC cold rolled plate zero cut are sold in more than 20 provinces, cities and all over the world. The company has strong technical force, complete production equipment, advanced production technology, perfect testing methods, and high-quality products.

The company's after-sales service team is a high-quality professional team. Most after-sales employees have rich service experience and have reached the level of after-sales engineer. The after-sales department implements the after-sales personnel responsibility system and a 24-hour response mechanism. The company's advanced customer relationship management system provides customers with "standardized and streamlined services". A sound customer relationship maintenance system, and a "one-stop" customer satisfaction tracking system, all reflect our strong after-sales service guarantee.

Leave a message