What are the top five B600L steel for car safety parts hot rolled plates mills in Myanmar

In recent years, in line with the development trend of iron and B600L steel for car safety parts steel industry at home and abroad, we have accelerated the transformation of development mode, promoted structural adjustment, and formed a rich product serie

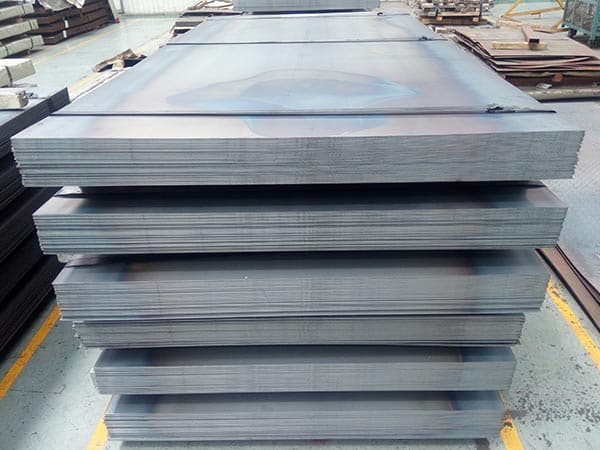

In recent years, in line with the development trend of iron and B600L steel for car safety parts steel industry at home and abroad, we have accelerated the transformation of development mode, promoted structural adjustment, and formed a rich product series of medium and thick plates, hot rolled steel coils, profiles, steel pipes, etc., which B600L steel for car safety parts are widely used in automobiles, long-span bridges, railways, machinery, ocean and so on fields. Meanwhile, we also provide deep processing for the steel materials.

The company is a professional manufacture and stock keeper of Q245R boiler steel plate, q345r boiler plate, 15CrMoR boiler steel plate, SA516 Gr 70 boiler steel plate, 16MnDR boiler steel plate, B600L steel for car safety parts, and so on steel materials. The steel product can be produced according to GB, ASTM, ASME, JIS, DIN and EN standards. The thickness range of the pressure vessel and boiler steel plates is 3mm - 180mm. The pressure vessel and boiler steel products are widely used in petroleum, chemical, paper, power, nuclear power, heat exchanger, condenser, food and beverage, medicine and other industries or engineering.

The mechanical properties of 20MnV steel are as follows: tensile strength 785 MPa, yield strength 590 MPa, elongation after fracture 10%, reduction of area 40%, impact absorption energy 55 J. B600L steel for car safety parts, 20MnV steel has good properties, good strength, toughness and plasticity, good hardenability and machinability. After carburizing, 20MnV steel can be directly quenched without secondary quenching to improve the core structure. The weldability of 20MnV steel is good, but there is temper brittleness at 300-360 ℃ during heat treatment.

The performance of heat treatment process reflects the difficulty of heat treatment and the tendency of defects of the steel. It mainly includes hardenability, superheat sensitivity, temper embrittlement tendency and oxidation decarburization tendency. The hardenability of B600L steel for car safety parts, alloy steel is high. The cooling method can be used slowly during quenching, which can reduce the deformation and cracking tendency of the workpiece. The addition of Mn and Si will increase the superheat sensitivity of steel. The strengthening effect of alloy elements on steel in quenching and tempering state is the most significant.

According to GBT3077, 42CrMo steel chemical composition should be within the range (%): 42CrMo carbon content is 0.38-0.45 (C), Silicon content is 0.17-0.37 (Si), Manganese content is 0.50-0.80 (Mn), Chrome content is 0.90-1.20 (Cr), Molybdenum content is 0.15-0.25 (Mo). The high Cr content contrivutes to high strength of 42CrMo steel, with min. yield strength of 930 Mpa, and min. tensile strength of 1080 Mpa. The common heat treatment for B600L steel for car safety parts, 42CrMo steel is quenching and tempering.

we are the best professional steel manufacturer in China. We can supply kinds of steel product size,if you want to purchase steel plate or steel pipe and other products. Please contact us freely. we can give you the B600L steel for car safety parts best price with high quality.

There is a careful, patient, enthusiastic and thoughtful after-sales team, a professional distribution, ultra-efficient warehouse and logistics center, a marketing team with marketing expertise, an innovative technology center with strong steel technology, an experienced manufacturing center with rigorous professionalism Quality Inspection Center, an operation team with many years of administrative management experience. Such a strong combination of teams makes BEBON a steel giant in Henan Province.

Leave a message