What are the top 10 S420MC steel for car safety parts hot rolled plates mills in Iran

The company always adheres to the S420MC steel for car safety parts principle of "quality first, user first", and takes every cooperation seriously. It is our biggest wish that the steel material, specification and quantity can fully meet the re

The company always adheres to the S420MC steel for car safety parts principle of "quality first, user first", and takes every cooperation seriously. It is our biggest wish that the steel material, specification and quantity can fully meet the requirements of users. With good reputation, high quality products and low price, we are willing to work together with old and new customers to create a great S420MC steel for car safety parts cause. Customers are welcome to visit our company at any time. We are always ready to support you.

30CrNi3MoV (675) high-strength steel is a new type of high-strength steel newly developed and put into use in China. It is a steel plate for armored vehicles. 30CrNi3MoV steel is developed by V microalloying on the basis of the original Cr-Ni-Mo series low-alloy ultra-high-strength steel, and appropriately adjusting the content of other alloying elements. The milling performance of 30CrNi3MoV steel is poor.

High strength steel is a kind of steel often used in engineering construction. With the improvement of technical level, the research and development of high strength steel in China has made remarkable achievements. The application of high strength steel S420MC steel for car safety parts in the construction field can reduce the steel consumption and building volume, and improve the building weight. That is one of the important reason why the high strength steel is so warmly welcomed nowadays.

The acicular ferrite pipeline steel can inhibit the formation of polygonal ferrite, promote the acicular ferrite transformation, and improve the precipitation strengthening effect of carbon and niobium nitride by adding molybdenum to reduce the transformation temperature of polygonal ferrite, so as to improve the strength of steel and reduce the ductile brittle transition temperature. The S420MC steel for car safety parts, tempered sorbite pipeline steel adopts the heat treatment process of quenching and tempering. The tempered sorbite structure is formed to meet the comprehensive requirements of thick wall, high strength and sufficient toughness.

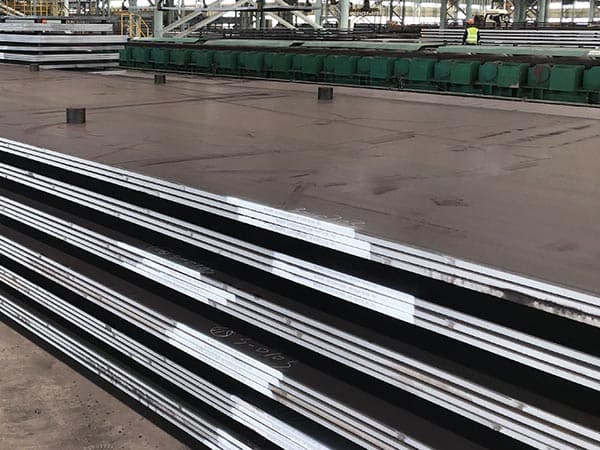

Our alloy steel plate and sheets are mainly used for weld fabrication of pressure vessels that require improved notch toughness for lower than ambient temperature service.Width: 1000mm to 4500mmThickness : 5mm to 150mmLength: 3000mm to 18000mmImpact tested 52° CS420MC steel for car safety parts, Supply Condition: As Rolled, Normalized Rolling, Furnace Normalizing, Vacuum Degassing, Simulated Post-Weld Heat Treatment or as per customer requirement.

It is a modern high-tech professional enterprise integrating scientific research, S420MC steel for car safety parts production and sales. The company is mainly engaged in the manufacture, installation and commissioning of boiler and pressure vessel, chemical, metallurgical, petroleum and other equipment, as well as S420MC steel for car safety parts process technology development, technology transfer and related technical consulting and technical services.

Adhere to the spirit of quality first and user foremost, carry out maintenance and other work according to the requirements of the buyer's contract, and ensure that the engineering project and product after-sales play their application effectiveness. Our company guarantees to carry out self inspection and self supervision according to the quality management policy proposed by our company, and deliver a high-grade, perfect and excellent system engineering to users.

Leave a message