What are the differences between black and painted steel for truck chassis assemblies

The company covers an area of 15,000 square meters and the plant construction area is 10,000 square meters. We have introduced more than 50 sets of advanced steel for truck chassis assemblies production equipment, auxiliary equipment and testing equipment

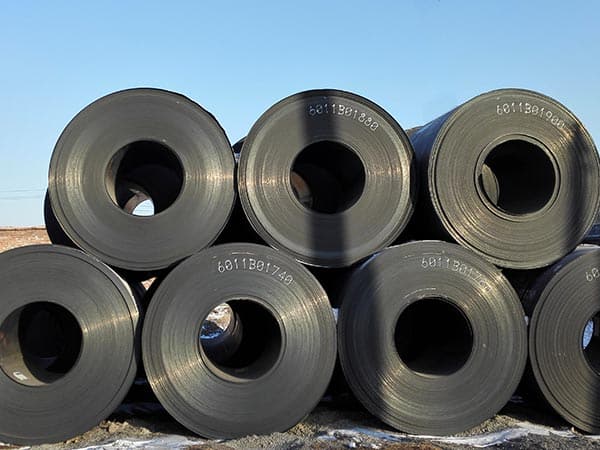

The company covers an area of 15,000 square meters and the plant construction area is 10,000 square meters. We have introduced more than 50 sets of advanced steel for truck chassis assemblies production equipment, auxiliary equipment and testing equipment at home and abroad, more than 260 employees, more than 20 middle and senior management staff, more than 10 professional and technical personnel, annual production capacity of 100,000 tons. Main products: flat steel, steel for truck chassis assemblies steel pipe, steel plate, section steel, steel structure processing parts, etc. We also accept incoming materials and annealing processing.

EN 10083/3-2006 42crmo4 is an industrial material. 42CrMo4 is used to manufacture forgings that require higher strength and larger quenched and tempered section than 35CrMo steel, such as large gears for locomotive traction, supercharger transmission gears, rear axles, connecting rods and spring clips that are heavily loaded. 42CrMo4 is also It can be used for oil deep well drill pipe joints and fishing tools under 2000m.

The weldability of steel for truck chassis assemblies is good. It means that under certain process and construction conditions, steel for truck chassis assemblies can obtain good performance after welding. Weldability is a measure of the hot workability of steel. Weldability can be divided into weldability in construction and weldability in use. Weldability in construction refers to the sensitivity of cracking in weld metal and near seam zone, and hardening sensitivity of steel in near seam zone. Good weldability means that under certain welding process conditions, the weld metal and steel near the seam do not produce cracks. Weldability in use means that the mechanical properties of weld and HAZ steel are not lower than those of base metal.

The effect of alloy elements on the properties of heat treatment methods for thick steel plate: the performance of heat treatment method reflects the difficulty coefficient level of heat treatment process and the tendency of defects caused by heat treatment process. The key points include cutting performance, over temperature sensitivity, quenching aging tendency and air oxidation carburizing tendency. steel for truck chassis assemblies, Carbon steel has high machinability, and slow cooling method can be used in heat treatment, which can reduce the deformation and cracking tendency of the products. The addition of Mn and Si will increase the over temperature sensitivity of steel.

20Mn2 steel has medium strength, and the properties of 20Mn2 steel and 20Cr steel are similar. The impact toughness and weldability of 20Mn2 steel at low temperature are better than those of 20Cr steel. The plasticity and machinability of 20Mn2 steel are high during cold deformation. The hardenability of 20Mn2 steel is higher than that of corresponding carbon steel, steel for truck chassis assemblies. Chemical composition of 20Mn2 steel: C: 0.17-0.24, Si: 0.17-0.37, Mn: 1.40-1.80. Mechanical properties of 20Mn2 steel: tensile strength ≥ 785 MPa, yield strength ≥ 590 MPa, elongation after fracture ≥ 10%, section expansion rate ≥ 40%, impact absorbed energy ≥ 47J.

our company is a professional steel for truck chassis assemblies API 5CT N80 casing pipe steel exporter and a steel Stockist in china. We keep more than 1000 tons API 5CT N80 casing pipe steel in stock every month. If you want to get the API 5CT N80 casing pipe steel price, please do not hesitate to contact us. Any need in API 5CT N80 casing pipe steel for truck chassis assemblies Chemical Composition and Mechanical Properties, please feel free to contact us by email or calling to us.

The company is deeply supported and loved by customers with its unique business philosophy and business model. The company has always been adhering to the "credibility first, integrity-based, quality first" purpose, and sincerely serve new and old customers. Over the past twenty years, the company has won the trust of customers by relying on good service and good reputation. Our aftersales team’s main responsibility is to deal with quality feedback and complaints from Customer.

Leave a message