What are the characteristics of qualified S960MC with EN10204-3.1 certificate

With high-quality S960MC with EN10204-3.1 certificate steel and professional services, we have won international praise in infrastructure, shipbuilding, oil and other industries, and gradually grow into a bright star in the steel export industry, while wi

With high-quality S960MC with EN10204-3.1 certificate steel and professional services, we have won international praise in infrastructure, shipbuilding, oil and other industries, and gradually grow into a bright star in the steel export industry, while winning unanimous praise from foreign customers. It has laid a foundation for the development of our S960MC with EN10204-3.1 certificate steel market and improved the control of steel plate production quality.

The corrosion resistance of stainless steel depends on the alloy elements contained in the steel. The chemical composition of S960MC with EN10204-3.1 certificate, stainless steel and acid resistant steel is different. The former is not necessarily resistant to chemical medium corrosion, while the latter is generally stainless. The better stainless steel also contains nickel. Adding molybdenum can further improve the atmospheric corrosion resistance of stainless steel, especially the corrosion resistance of chloride containing atmosphere.

High wear resistance: fully automatic CNC stacking equipment, independent of manual S960MC with EN10204-3.1 certificate welding technology, produces fully qualified high-quality products. Special automatic welding technology enables the chromium content of wear-resistant layer to be controlled at more than 28%, and the S960MC with EN10204-3.1 certificate hardness is between 58-62, which fully ensures that our wear-resistant layer has continuous good and balanced wear resistance. The wear test in metallurgy, cement and other industries shows that the wear resistance of the wear-resistant layer of the surfacing composite S960MC with EN10204-3.1 certificate wear-resistant steel plate is more than 30 times that of the 16Mn plate with the same thickness.

The basic phases of S960MC with EN10204-3.1 certificate, structural steel in the annealed state are ferrite and carbide. The alloy elements are dissolved in ferrite to form alloy ferrite, which depends on solid solution strengthening to increase strength and hardness, but at the same time reduce plasticity and toughness. The addition of alloying elements reduces the carbon content of the eutectoid point, which increases the proportion of pearlite in the structure and reduces the distance of the pearlite layer. This also increases the strength of the steel and reduces the plasticity.

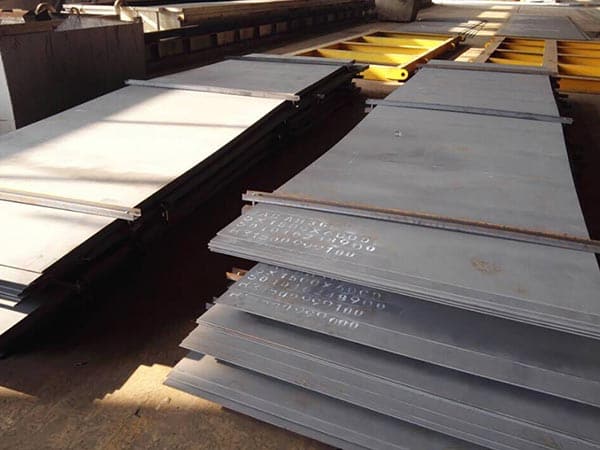

BBN steel S960MC with EN10204-3.1 certificate 15mm to 35mm thick size: 15*2120*5620, 17.5*2320*13000, 18*2450*5500, 20*3000*5000, 19*2580*4700, 19.5*1970*4000, 20*1600*7740, 20.5*2370*7000, 21*2650*7500, 21*1920*8220, 22*1380*7650, 22*1800*8000, 22.5*1680*8450, 23*3000*11980, 23.5*2080*8100, 24*1560*6200, 25.5*2330*8300, 26*3010*8100, 26.5*2000*7000, 27*2550*6800, 27.5*2700*5500, 29*2550*9000, 29*2870*12000, 32*3300*6000, 33*2340*6700, 34*2120*6100, 35*1300*4100.

Since its establishment, the company has participated in several key railway and highway projects. After years of development, the company’s S960MC with EN10204-3.1 certificate domestic market has been exported to more than a dozen provinces and cities including Kunming, Shenzhen, Hunan, Sichuan, Shanghai, Nanjing, Heihe, Jilin, Inner Mongolia, and Xinjiang . International trade is exported to Kazakhstan, South Korea, Vietnam, South Africa and many other countries, and has been well received by customers.

After-sales service team is a key department to test the steel quality. Product quality is always the foundation of our survival and development. The company's full inspection from raw materials to finished products; and implements standardized, scientific, and strict internal quality control and management systems in accordance with the process flow during the production process; products can only leave the factory if qualified, and follow-up problem solving systems are implemented in after-sales services to guarantee the customers’ interest.

Leave a message