Main factors affecting EN 1.0984 EN 10149-2 auto steel price

Focusing on the energy conservation and emission reduction objectives proposed by the municipal government, the company gives full play to the advantages of EN 1.0984 EN 10149-2 auto steel circular economy formed after the comprehensive completion and ope

Focusing on the energy conservation and emission reduction objectives proposed by the municipal government, the company gives full play to the advantages of EN 1.0984 EN 10149-2 auto steel circular economy formed after the comprehensive completion and operation, and vigorously promotes the implementation of energy conservation objectives. Through measures such as energy saving, technological innovation and EN 1.0984 EN 10149-2 auto steel management strengthening, the energy saving target of annual reduction of added value energy consumption by 7%. It has made great contribution to energy saving of over completion.

H13 tool steel is the most widely used and most representative hot work die steel. Its main characteristics are:(1) EN 1.0984 EN 10149-2 auto steel has high hardenability and high toughness;(2) Excellent thermal crack resistance, water cooling can be used in the work place;(3) With moderate wear resistance, carburizing or nitriding processes can also be used to increase the surface hardness, but the thermal crack resistance should be slightly reduced.

EN 1.0984 EN 10149-2 auto steel, low alloy high strength steel has good weldability. Welding is the most common method to construct engineering structure, so the steel used in engineering structure requires good welding performance. Low alloy high strength steel has low carbon content, low alloy element content and good plasticity, so it is not easy to produce quenching structure and crack in the weld area, and the addition of Ti, Nb, V can also inhibit the grain growth in the weld area. Therefore, most of the low alloy high strength steels have excellent welding performance and no heat treatment is required after welding.

The composition characteristics of low alloy high strength steel are low carbon ≤0.20%, low alloy, and total alloying elements is less than 3%. The low carbon content is to meet the process performance requirements of EN 1.0984 EN 10149-2 auto steel, low alloy high strength steel for engineering structural parts such as plasticity, toughness, weldability and cold deformation; adding a small amount of alloying elements (mainly Mn) to achieve the purpose of improving mechanical properties. Mn not only has a significant strengthening effect on ferrite, it can also reduce the cold brittle temperature of steel, increase the amount of pearlite in the steel, and further improve the strength.

A514 gr.H quenched and tempered alloy steel sheet chemical composition (melting analysis)%C: 0.12-0.21, Si: 0.20-0.35, Mn: 0.95-1.30, P max.: 0.035, S max.: 0.035, Cr: 0.40-0.65, Ni: 0.30-0.70, Mo: 0.20-0.30, V: 0.03-0.08, B: 0.001-0.005The mechanical properties in thickness (mm)T≤65Yield strength (≥Mpa): 690Tensile strength (Mpa):760-895Elongation in ≥,%: 18

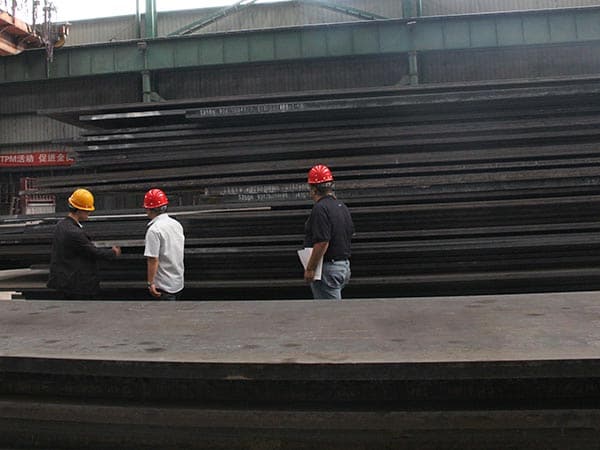

Our company is one of the famous steel suppliers in China, specializing in the production of steel plates, steel pipes and other steel products. If you are interested in steel products, or need to purchase a large number of EN 1.0984 EN 10149-2 auto steel steel plates and pipes. Please contact our company directly, we will provide the most favorable price and the most perfect system, our employees have professional product knowledge. We hope to provide you with high quality products.

Respect customers and treat each other sincerely. Customers are always right. Always remember that the user is the God of the enterprise, respect the customer, and accept the customer's opinion modestly is the guarantee of the long-term development of the enterprise. Adhere to this concept, so that the service and the product are the same, long-term.

Leave a message