Is B700L steel for construction machinery parts hot or cold rolled?

The cold rolling precision bright pipe system produced by our factory has smooth appearance, uniform wall thickness, no oxide layer and high precision. The inner hole of B700L steel for construction machinery parts steel pipe can be divided into round, sp

The cold rolling precision bright pipe system produced by our factory has smooth appearance, uniform wall thickness, no oxide layer and high precision. The inner hole of B700L steel for construction machinery parts steel pipe can be divided into round, spline and plum blossom, which is widely used in automobile, motorcycle, electric power, petrochemical, ship, aerospace, bearing, pneumatic components, oil cylinder, boiler equipment, medical equipment, fitness equipment and other industries. Materials can be divided into: 10#, 20#, 35#, 45#, 40Cr, 16Mn, etc. According to the needs of users, we can make all kinds of national standard non-standard precision pipes. Special B700L steel for construction machinery parts materials and specifications can be ordered in advance.

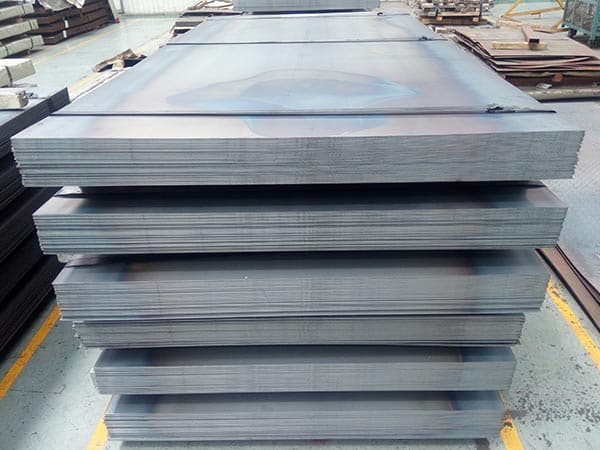

Hot-rolled B700L steel for construction machinery parts steel plate mill operates heavy plate cutting, galvanized steel plate, steel plate punching, hot-rolled steel plate manufacturing, spring steel plate, 35crmo steel plate, 40cr steel plate, Q345C steel plate, 12cr1mov alloy plate, 16mn steel plate, A573 grade 70 pressure vessel plate, 15crmo alloy Steel plate, A516 grade 70 boiler plate, bridge structure steel plate, B700L steel for construction machinery parts corrosion-resistant steel plate, composite steel plate, pipeline steel plates, oil tank steel and alloy steel plate.

The surface quality of pickling coil is very good. Compared with ordinary hot-rolled plate, B700L steel for construction machinery parts, the surface quality of hot-rolled pickling coil is improved in addition to the oxide scale on the surface, which is convenient for welding, oiling and painting. The accuracy of pickling coil specification is high. After leveling, the shape of the plate changes to a certain extent, thus reducing the deviation of unevenness, improving the surface finish and enhancing the appearance effect of pickling coil.

The B700L steel for construction machinery parts, wear resistant steel plate is composed of low carbon steel plate and alloy wear-resistant layer, and the alloy wear-resistant layer is 1/3 ~ 1/2 of the total thickness. The alloy wear-resistant layer and the base plate are metallurgically bonded. When working, the base plate provides comprehensive properties such as strength, toughness and plasticity to resist external forces, and the alloy wear-resistant layer provides wear-resistant properties to meet the requirements of specified working conditions.

Hardness comparison between Q345B steel and NM450 steel: wear resistant steel for construction machinery requires high wear resistance, high toughness, impact resistance, easy welding, easy forming and other high-performance characteristics. The main index of wear resistance is the surface hardness. The higher the hardness, the better the wear resistance. Compared with B700L steel for construction machinery parts, Q345B steel, the hardness of NM450 steel is only increased 3 times, but the average service life is increased 6-8 times under the same working conditions.

For ASTM A573 Grade 70/A573 Gr.70 carbon manganese silicon steel plates, our company would issue the original mill test certificate B700L steel for construction machinery parts EN 10204 3.1 for clients when arrange delivery, so that clients can trace the A573 Gr.70 plates origin easily.

The company is deeply supported and loved by customers with its unique business philosophy and business model. The company has always been adhering to the "credibility first, integrity-based, quality first" purpose, and sincerely serve new and old customers. Over the past twenty years, the company has won the trust of customers by relying on good service and good reputation. Our aftersales team’s main responsibility is to deal with quality feedback and complaints from Customer.

Leave a message